Semi automatic filling machine key features:

Product name:Semi-automatic vertical constant temperature filling machine

Usage:Jam, Lotion

Function:Filing

Suitable for:High Viscous Products

Capacity:10-30 Bottles/min

Filling range:10-300ml

Material:SUS304

Filling nozzles:1 Nozzle

Control:Control+Foot Pedle

Operation:1 Person

Production description:

Introducing our Semi-Automatic Vertical Temperature-Controlled Filling Machine, the perfect solution for filling jelly-like substances that require heating to a specific temperature. Designed for professional use, this machine offers precise temperature control and efficient filling capabilities, making it ideal for a range of industries.

With its vertical design, this filling machine takes up minimal space and is easy to operate. Its temperature control system ensures that the product is heated to the desired temperature, allowing for consistent and accurate filling. Plus, its semi-automatic operation makes it easy to fill containers quickly and efficiently.

Whether you are filling jars of jam, bottles of syrup or any other substance that requires heating, our Half-Automatic Vertical Temperature-Controlled Filling Machine is the perfect tool for the job. Its professional-grade construction and reliable performance make it a must-have for any business looking to streamline their filling process and improve overall efficiency.

Production details:

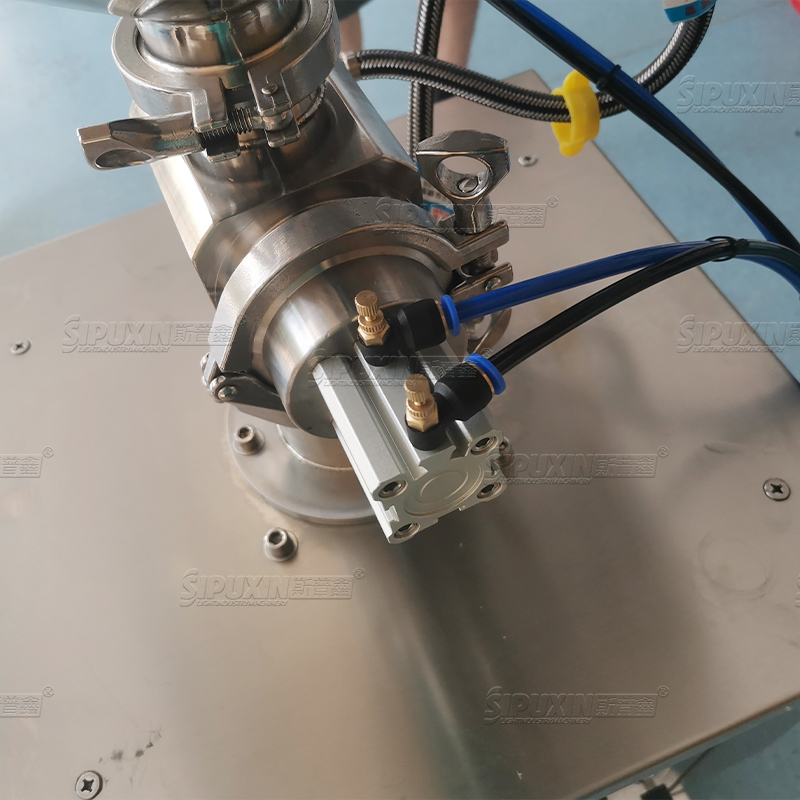

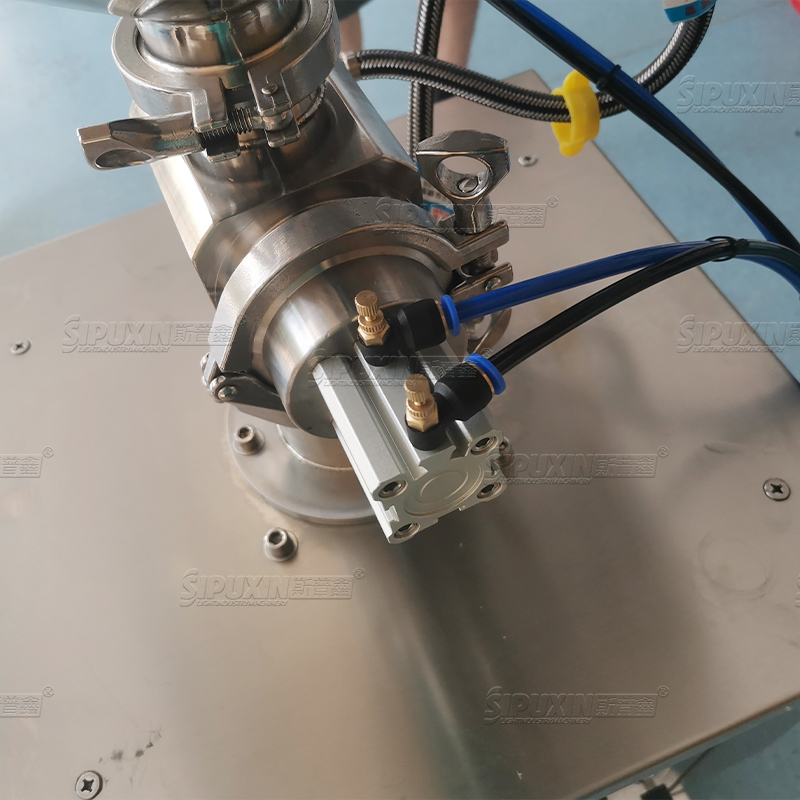

Air connection

The connection to the pneumatic pump inside the machine, which is responsible for pushing the material down through the piston, plays a pivotal role in ensuring high-quality outcomes in various industrial processes. Here's how this mechanism contributes to quality assurance:

the connection to a pneumatic pump inside the machine, which facilitates material delivery through a piston, is a critical component in ensuring good quality in various manufacturing processes. It offers precision, uniformity, contamination control, and automation, all of which are essential for maintaining product integrity and consistency

Heated filling nozzle

The heated filling nozzle, crafted from SUS 316 stainless steel, offers both durability and customization options to cater to your specific bottle-filling needs. Here's how these features can benefit your production process:

the heated filling nozzle made of SUS 316 stainless steel, with customization options, offers a versatile and cost-effective solution for your bottle-filling requirements. It ensures both durability and hygiene, making it an essential component in industries where precision, cleanliness, and product quality are paramount.

Control pannel

The simplicity of button controls often translates to lower equipment and maintenance costs. The reduced complexity means fewer components and less potential for malfunctions, resulting in cost savings over the machine's lifecycle.

controlling the machine with straightforward buttons is a user-centric approach that prioritizes ease of operation, efficiency, and reliability. It minimizes the potential for errors, ensures consistent performance, and promotes accessibility. This user-friendly interface is particularly valuable in industries where rapid and error-free machine operation is essential for productivity and product quality.

Value port

Combining ease of operation with high filling accuracy is a crucial goal in many industrial and manufacturing processes. Achieving this balance benefits both efficiency and product quality. Here's how these two factors can be harmonized:

1. User-Friendly Interface: Implement an intuitive and user-friendly interface for the machine's control system. This might include a touchscreen panel with clear, simple instructions and buttons. Operators should be able to start, stop, and adjust the machine's settings with ease.

2. Digital Controls: Use digital controls that allow for precise adjustments. Digital readouts and controls make it easy to set and fine-tune parameters like fill volume, speed, and timing, enhancing accuracy.

3. Automatic Calibration: Implement automatic calibration features to simplify setup. This ensures that the machine is accurately calibrated for different materials and container sizes, reducing the need for manual adjustments.

By combining these elements, you can create a filling system that is both easy to operate and capable of delivering high filling accuracy. This ensures efficiency in production processes while consistently meeting quality standards.

FAQ

packing

English

English