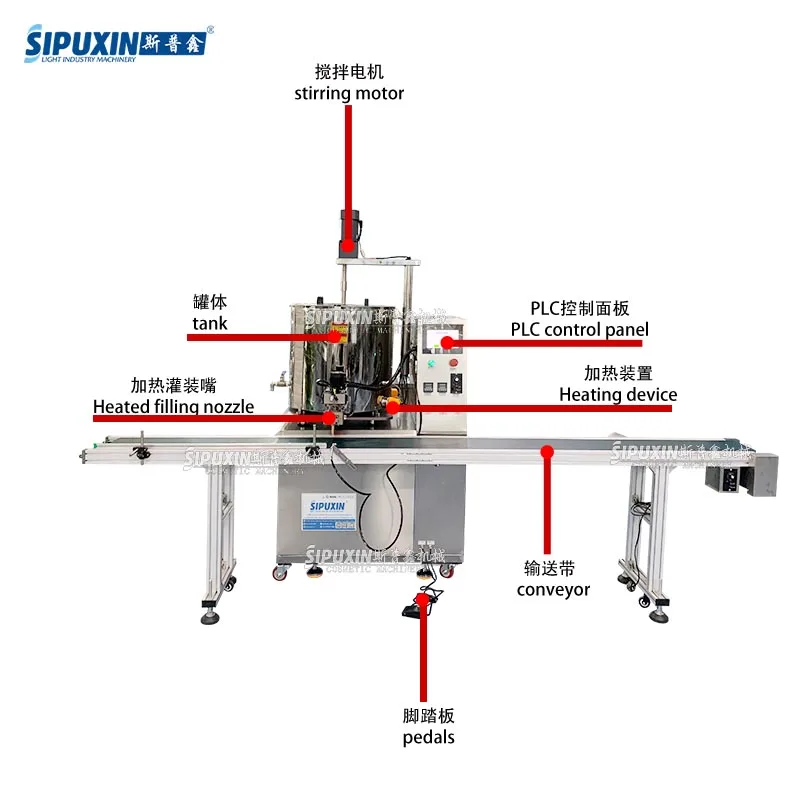

Filling Nozzle Heating System

The filling nozzle is equipped with an independent heating system, allowing precise temperature control to ensure smooth and

consistent filling. This system prevents blockages by keeping heat-sensitive or viscous materials at an optimal temperature,

reducing the risk of solidification. With adjustable temperature settings, it accommodates various materials like wax, honey, or creams, ensuring uniform flow and accurate filling. This feature enhances efficiency and reliability, making it ideal for

industries that require precise handling of heated substances.

English

English