6 Nozzles Automatic filling machine key features:

Feature:High Precision Filling Level

Control:PLC+ Touch Screen

Advantage:Efficiency

Processing:Rinsing, bottling ,capping

Power:According to customer's requests

Filling nozzles:6 Nozzles

Product name:6-head filling capping and capping O-shaped mold rotary line

Suitable:All Liquid Products

Certification:CE Certified

Material:Stainless Steel 304/316

Condition:New

Application:Food, Beverage, Chemical

Driven Type:Hydraulic

Weight:700kg

Key Selling Points:High-accuracy

Feature:Efficiency

Control:botton

Homogenizer Speed:0-3600 R/min

Mixing speed:0-65 R/min

Advantage:Easy to operate

Function:Stirring emulsification

Opening way:Electric

Production description:

The 6-Head Rotary Filling Capping O-Ring Moulding Line is a customized product

designed for efficient and fast filling and capping operations. Equipped with servo

filling technology, this product ensures quicker filling speeds and higher precision.

The rotary line is designed to operate in a continuous cycle, ensuring maximum

productivity and efficiency. With its advanced features and reliable performance, this product is ideal for businesses looking to streamline their filling and capping operations. Invest in the 6-Head Rotary Filling Capping O-Ring Moulding Line today and experience unmatched efficiency and productivity in your operations.

Production details:

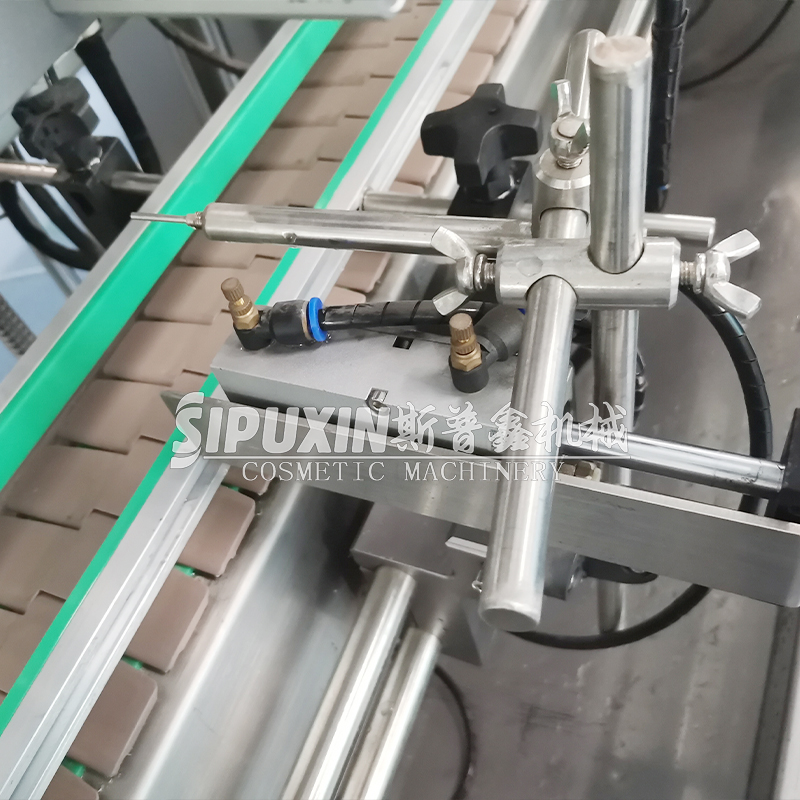

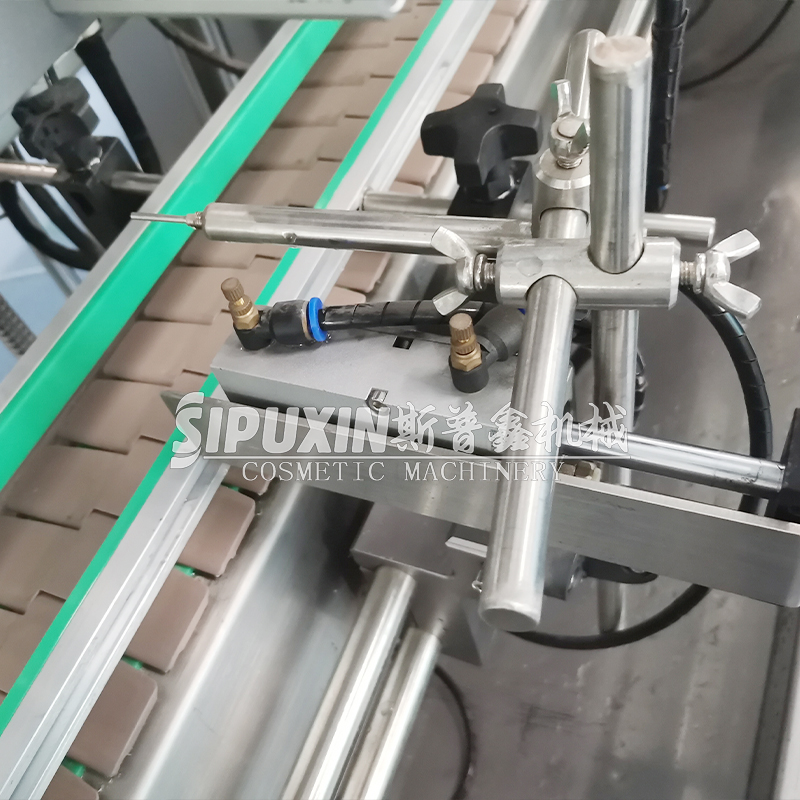

Filling nozzles

The parts in contact with materials are made of SUS316 stainless steel. which meets GMP requirements.

The filling volume and filling speed can be adjusted arbitrarily, and the filling accuracy is high.

The filling bulkhead adopts an anti-drip device.

PLC control panel

The touch-screen control panel uses Siemens world-renowned brands,with guaranteed quality,

convenient for the operator to operate various functions,adjustable frequency,quick start,

and immediate stop which is very sensitive.Different languages can be selected

Bottle sensor

If there are 4 bottles, there will be a baffle to block the products behind, so that the empty bottles of the production line will not be blocked, and then filled .

Automatic transfer conveyor

This is an automatic transfer conveyor, and the bottles flow in sequence when working.

English

English