| Machine weight | About 2000kg |

| Product name | Liquid soap /cosmetic paste cream making machine |

| Material | SUS304/316L |

| Function | Homogenizing and mixing machine |

| Driven Type | Steam or Electric heating |

| Type | Homogenizer and mixing, Heating, Emulsifier |

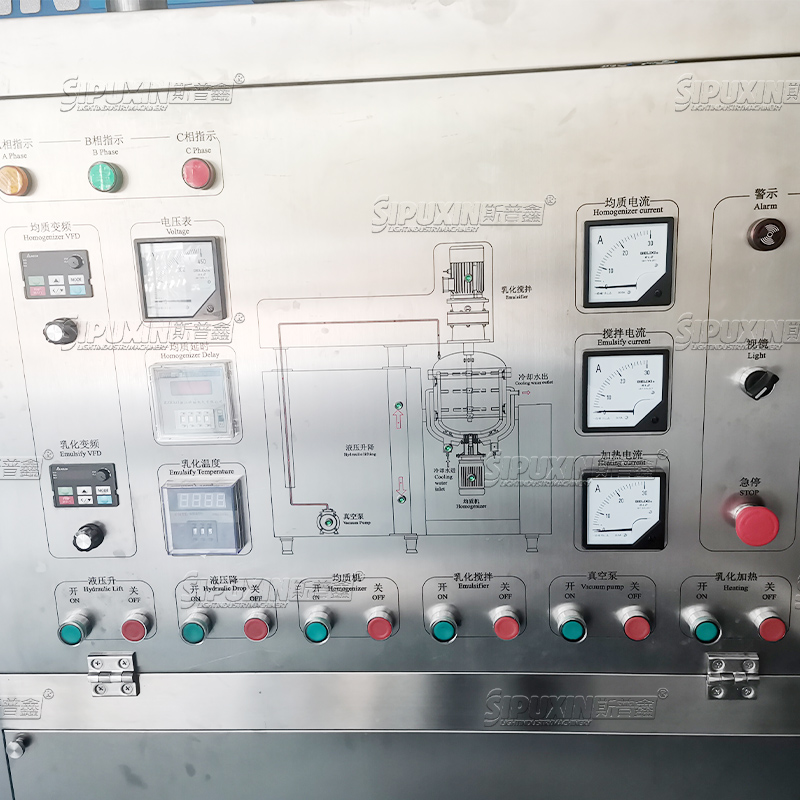

The control panel convenient for the operator to operate various functions, adjustable frequency, quick start, and immediate stop, which is very sensitive.

Mixing system

the mixing system consists of inter fix paddle,scrapper mixer and clockwise direction blender,which the retation speed can reach 63 times per minute.and the perfect mixing result increase the mixing efficiency and performance,as well as heating efficiency.

the steam product form the main tank will be cooled by this condenser,transfer the steam into liquid.

With stator, rotor. it can work for a long time with fine and smooth, high evenness, energy saving. Material produced by emulsification pump can be directly devoted into next producing, or transferred back to tank for circulation.

Machine composition:

The vacuum homogenizer is mainly composed of high shear vacuum emulsifying system , the reactor system,mixing system and lifting system , etc..

Condenser

1)a component of a refrigeration system, is a type of heat exchanger that can convert gas or vapor into a liquid, transferring heat from the pipe to the air near the pipe in a rapid manner.".

2)The working process of the condenser is an exothermic process, so the temperature of the condenser is relatively high.

3)The necessity of condensers is based on the second law of thermodynamics - according to the second law of thermodynamics, the spontaneous flow direction of thermal energy within a closed system is unidirectional, that is, it can only flow from high heat to low heat. In the microscopic world, microscopic particles that carry thermal energy can only change from order to disorder. Therefore, when a heat engine has energy input to do work, it must also have energy output downstream, so that there is a thermal energy gap between the upstream and downstream, the flow of thermal energy will become possible, and the cycle will continue.

Usage and Application:

Our machine is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, food industry, paint and ink, nanometer materials, petrochemical industry, printing and rubber, electrics and electronics and fine chemical industry etc., the emulsifying effect is more prominent for materials of high base viscosity and high solid content.

English

English