The 2000L CIP (Clean-In-Place) Cleaning System is an advanced and efficient solution designed to meet the rigorous cleaning and sanitation requirements of industries such as food and beverage, pharmaceuticals, biotechnology, and cosmetics. This system ensures optimal hygiene, reduces downtime, and enhances operational efficiency by automating the cleaning process for tanks, pipelines, and processing equipment without the need for disassembly.

Key Features:

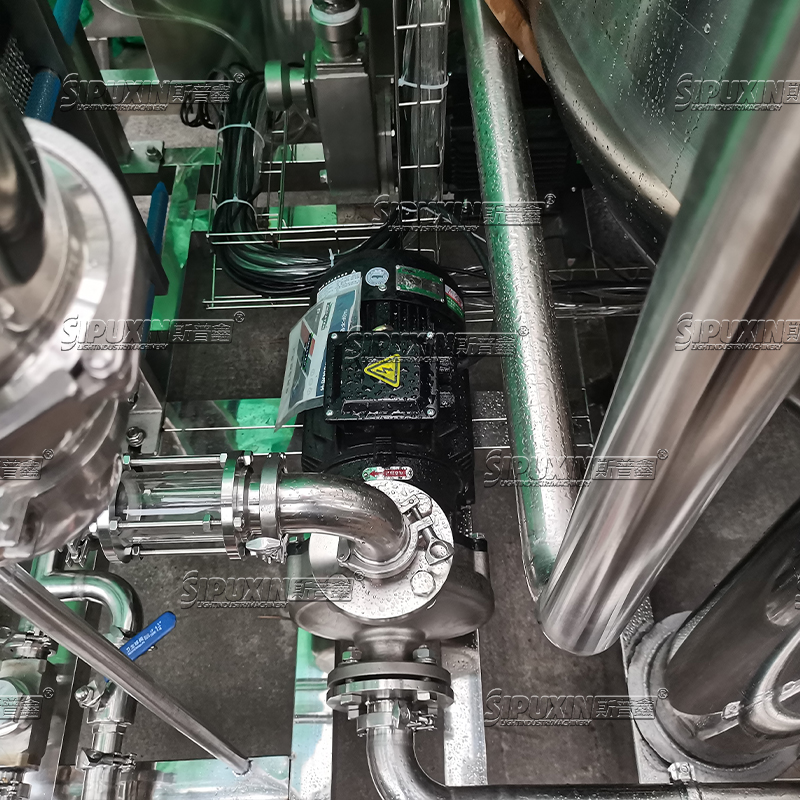

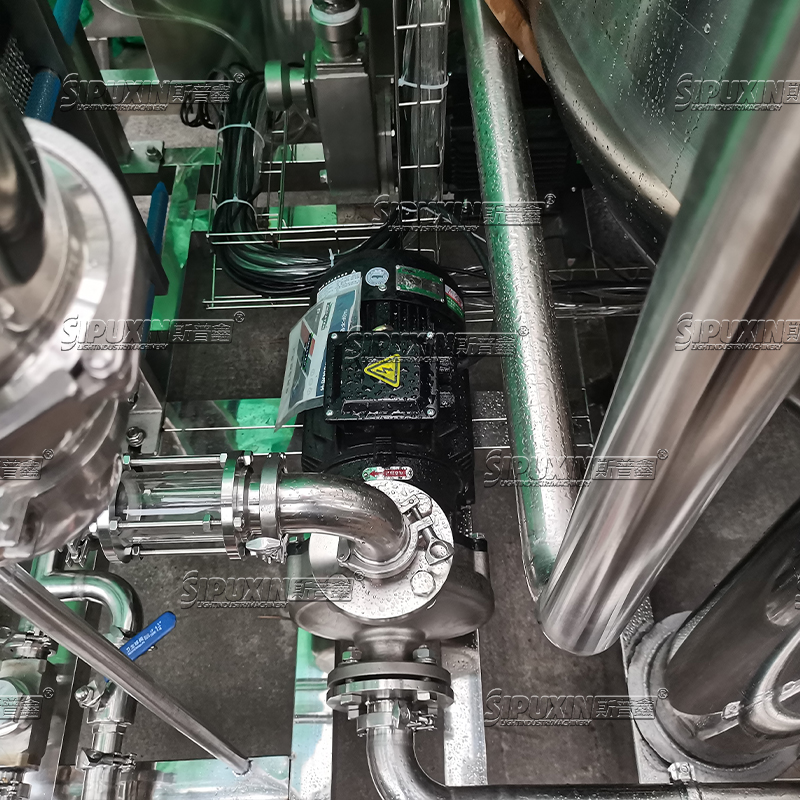

pump

pneumatic valve

pneumatic valve

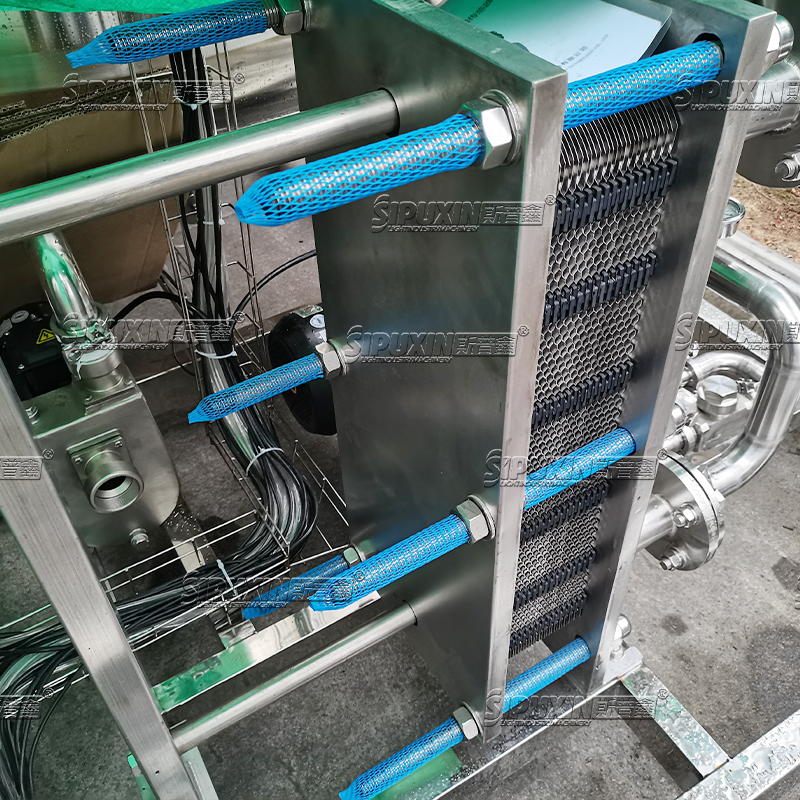

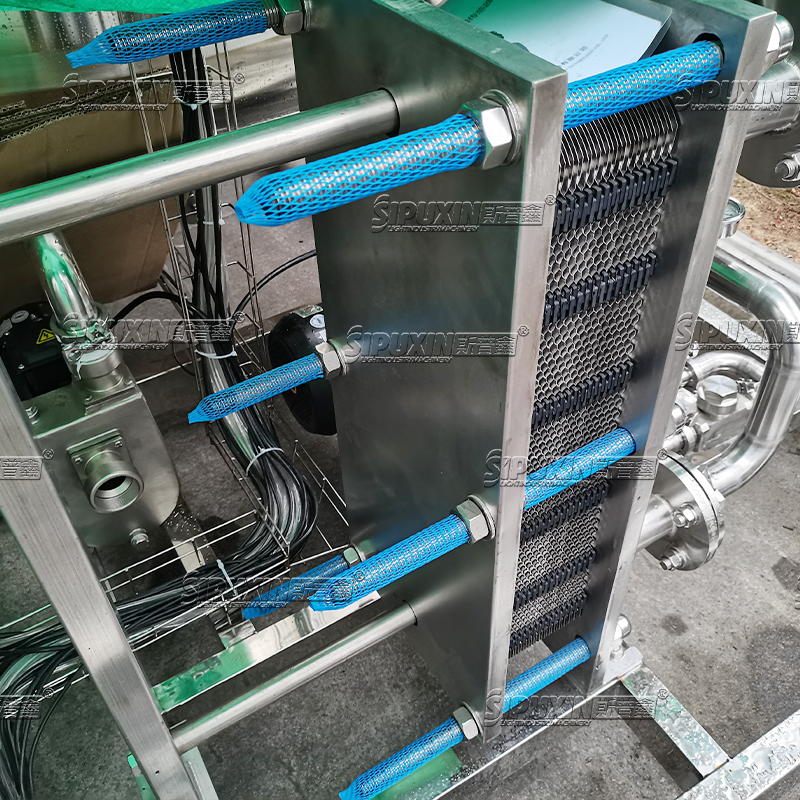

heat exchanger

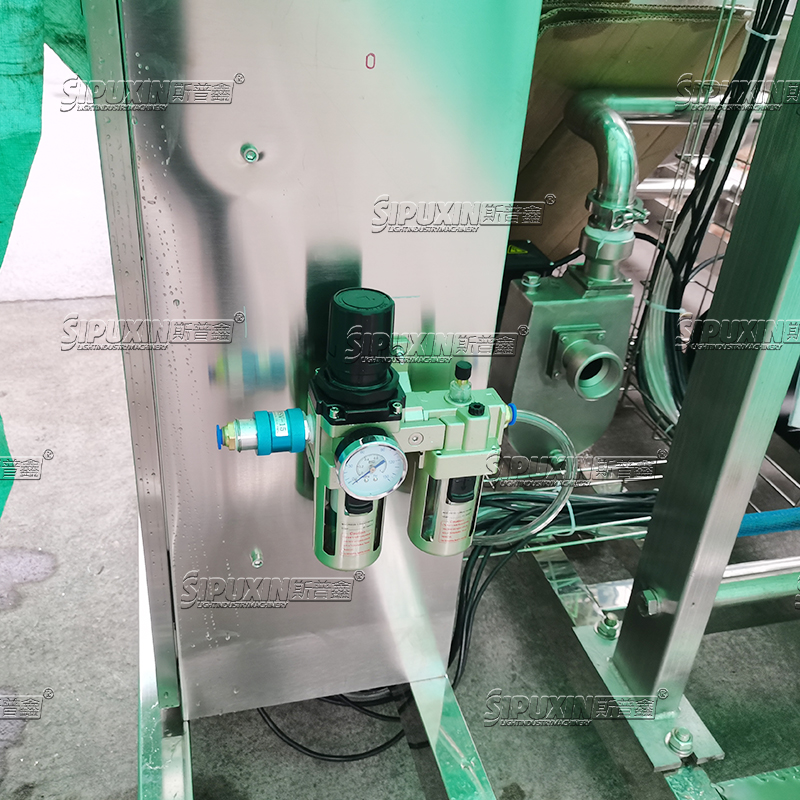

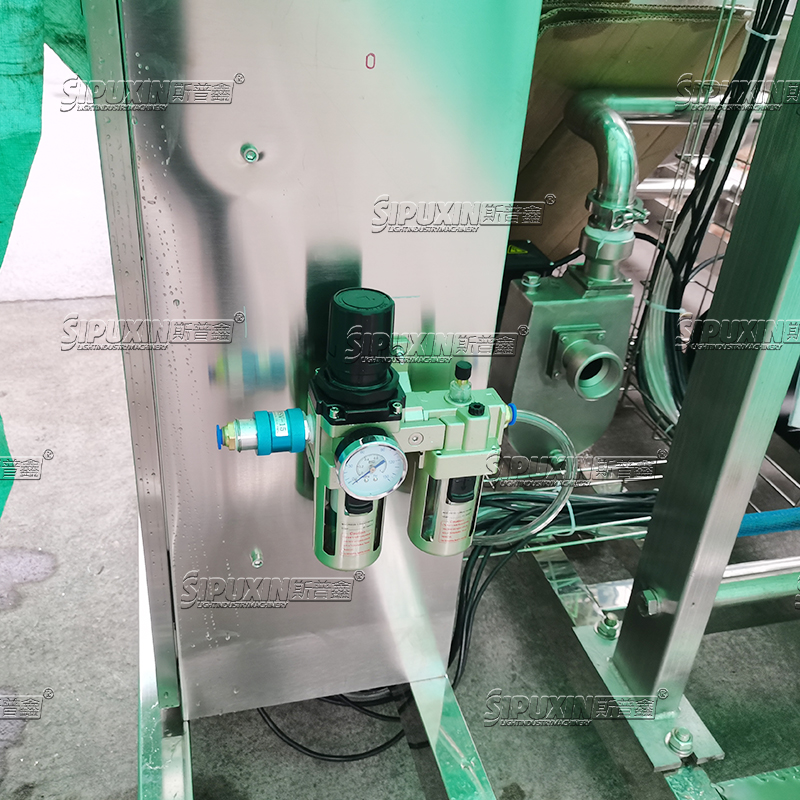

oil-water separator

1. High Capacity: With a 2000-liter capacity, this CIP system is ideal for medium to large-scale operations, ensuring thorough cleaning for extensive production setups.

2. Automated Operation: Equipped with a programmable logic controller (PLC), the system allows for fully automated cleaning cycles, reducing manual intervention and ensuring consistent results.

3. Multi-Stage Cleaning: The system supports multiple cleaning stages, including pre-rinse, caustic wash, acid wash, and final rinse, tailored to remove various types of residues and contaminants.

4. Energy Efficiency: Designed with energy-saving features, the system minimizes water and chemical consumption while maintaining high cleaning performance.

5. Durable Construction: Built with high-quality stainless steel (AISI 304/316), the system is corrosion-resistant, durable, and compliant with industry hygiene standards.

6. Customizable Options: The system can be customized to meet specific customer requirements, including additional tanks, pumps, or filtration units.

7. User-Friendly Interface: The intuitive touchscreen interface allows operators to easily set up, monitor, and adjust cleaning parameters.

8. Safety Compliance: Equipped with safety features such as pressure and temperature sensors, the system ensures safe and reliable operation.

Product Packaging

Click here to edit your content.

Click here to edit your content.

Click here to edit your content.

SCOPE OF APPLICATION

Cleaning of fermentation tanks, storage tanks, and mixing vessels in the food and beverage industry.

- Sanitization of pipelines and processing equipment in pharmaceutical and biotechnology facilities.

- Maintenance of hygiene standards in dairy, brewery, and cosmetic production lines

Benefits:

- **Improved Hygiene**: Ensures thorough cleaning, reducing the risk of contamination and product spoilage.

- **Time and Cost Savings**: Automates the cleaning process, reducing labor costs and minimizing production downtime.

- **Environmental Sustainability**: Optimizes resource usage, contributing to eco-friendly operations.

- **Consistent Performance**: Delivers reliable and repeatable cleaning results, ensuring compliance with industry regulations.

|

Company Profile

Guangzhou Sipuxin Light industry machinery Co., Ltd. s an intelligent manufacturing integrator engaged in cosmetic machinery, pharmaceutical equipment food machinery. Main products include Vacuum homogenizing emulsifier, Mixing tank,RO water treatment, Storage tank, CIP cleaning system,Filling/Capping/Labeling machine, Ink jet/laser printing machine and other packing machine, We have passed CE, BV TUV SGS quality certificate and coincident with GMP standard.

our modern factory in Yangzhou occupies 10000+ square meters. Guangzhou factory occupies 6000+ square meters we have advanced manufacturing and testing equipment, Take quality as the root, accumulate bit by bit improvements, rigorous process control,and implement standardized operations. Through CAD and 3D dynamic simulation, we are capable of optimizing the effect of the whole production process, easily making clients clear about working flow of the whole project, and bringing clients professional and real product effect Our professional sales team is able to help you select the most suitable model equipment 500 designs in 1000+ square meters modern showrooms for you to choose And we are able to customize new equipment according to your special request.

We support customers One-stop Turkey service from cosmetic factory GMP purification room decoration. formula. raw material. packaging material, equipment model selection. machine layout design. abroad installation. work flow guidance. Operating training for Cream line /Liquid line / Perfume line Toothpaste line Vaseline line /Lipstick line/ Corrosive chemical line. We will keep on repaving customers’ care via exquisite craftsmanship and continua improvement in product design. manufacturing. quality and service. Choosing Sipuxin machinery, wise choice makes success

|

Production Process

Certifications

English

English